Annual cylinder inspections are not that bad

The article, “UK under pressure to test cylinders annually,” published in the previous issue (#79) was informative, but appeared to be unfairly attacking standards in the United States. Without getting into some of the specific arguments, since they are subjective, I would like to address the misinformation on how annual cylinder inspections are conducted in many countries.

Tags & Taxonomy

Factfile

Don Kinney is the owner of Cylinder Training Services and has been teaching cylinder inspectors since 2001. He has developed training programs for using and inspecting cylinders, and has developed tools for conducting a proper inspection of those cylinders. He is the author of the ITI manual for visual inspection procedures and helped develop the ITI visual cylinder inspection program. He has authored over 12 articles on inspections, cleaning and rules and regulations involving high-pressure cylinders.

I understand in the United Kingdom, a scuba cylinder undergoes a visual inspection every 30 months and a hydrostatic requalification every five years. The UK dive industry was upset that the ISO (International Organization for Standardization in Europe) was looking at an annual visual inspection standard for cylinders. The process that the Inspectorate for Diving Equipment Servicing and Testing (IDEST) requires for a scuba cylinder inspection is a very thorough inspection, and I support all the steps. My concern with the aforementioned article is how it describes how cylinders are inspected in the United States: “...the valve is whipped off, a technician takes a look and puts the valve back in.” This could not be further from the truth.

Same procedure

We follow all the steps listed by IDEST, apart from the mandatory use of a Go/No Go gauge (see info box right) for the threads and mandatory valve rebuild.

I am not saying that the use of a Go/No Go gauge is not beneficial. There have been several incidents when the wrong valve is placed in the wrong cylinder. That, in turn, damages the threads and makes the cylinder unsafe, creating the possibility of a rupture. However, if an untrained person forces the wrong valve on the cylinder, at some other point in its use after the inspection, then no training can predict that error. During a proper visual inspection, with or without a gauge, the damage to the threads should be obvious to any properly trained inspector.

Rebuilding valves

We also train inspectors in the process of rebuilding valves. It is not mandated to rebuild the valve if it is working properly. The cylinder inspectors are trained to test the valve and determine their continued safe use. They can voluntarily take it upon themselves to repair or rebuild the valve or tell the owner that the valve did not pass and therefore was not placed back on the cylinder. In either circumstance, it is documented on the inspection form and final determination is made by the inspector and user.

I was also bothered by the statement: “This new ISO standard is being driven by a number of nations, including those that primarily dive with aluminum diving cylinders, where there have been issues with cylinder necks cracking.”

I do not know of a nation that primarily dives with aluminum cylinders. There are currently steel, aluminum and composite cylinders approved for diving. Each one of these materials has its positives and negatives, and the diving consumers generally drive the market.

Some like steel for the buoyancy characteristics, others like aluminum because of its corrosion characteristics and others enjoy composites because of their weight and increased pressures. However, all cylinders have their concerns when placed in the hands of users.

Cracks are rare

The stated issue of cracks in the necks of aluminum cylinders was years ago and involved only one specific alloy. Even within that alloy, ruptures are rare. Out of over 40 million cylinders manufactured with the 6351 alloy, only 20 were suspected of rupturing due to cracking (web stats). So, using the math, that is less than a .0000005 percent chance of a rupture with that one specific alloy. I’d like to state that ALL cylinders are safe—if inspected regularly, used properly and removed when they become unsafe.

Tap stop marks

The article also stated that 75 percetn of cylinder failures are due to issues with the threads. I cannot dispute that claim without seeing the data being mentioned. Without seeing the specific data, I would guess that part of the issue is machine marks in the threads.

There is a common concern when inspecting a cylinder’s threads and interpreting the results. We find that many people see a tap stop mark, and unjustly name it a crack or flaw within the threads. A tap stop is simply a machining mark and has no effect on the structural integrity of the cylinder.

I would say that tap stop marks are common on many cylinders, and not a reason to fail a cylinder. I state that all cylinders have a rare probability of cracking; whether they are aluminum or steel. Other flaws in the cylinder threads (improper valves) are normally caused by the user and should be caught by the inspector during the visual inspection process.

All treated equal

Furthermore, it was stated in the article that in the US, cylinders are not all treated the same way, and there is a classification for “sport and recreation.” I have never heard that phrase and have no idea where it would have been found.

In fact, when we train visual inspectors, we train them to inspect all cylinders regardless of usage. A cylinder may be used in scuba, fire service, beverage or scientific industries. It does not matter what industry; all that matters is that the cylinder is safe to use.

This is determined by wall thicknesses, obvious dents, threading concerns or other safety concerns noted during the inspection. I can more easily argue that most cylinders are “commercial cylinders” since they are all used in industries that exchange commerce.

A question of cost?

I do not know if the proposed standard would have put the divers at risk. The argument is made that with an increased cost of an annual inspection, divers would have found ways to avoid the new procedures. The question should become: What fee is the consumer charged for the annual inspection?

Since the article has already focused on the United States. I will use some pricing from that region. Depending on the inspection facility, the consumer pays US$15-25 for an annual inspection. They then pay an additional fee of $20-25 every five years for the hydrostatic requalification.

It has been my experience that most divers have no problem paying $25 every year to ensure the safety of their cylinders. And I can also say that paying $25 per cylinder per year is a lot less expensive than buying and maintaining a personal compressor system.

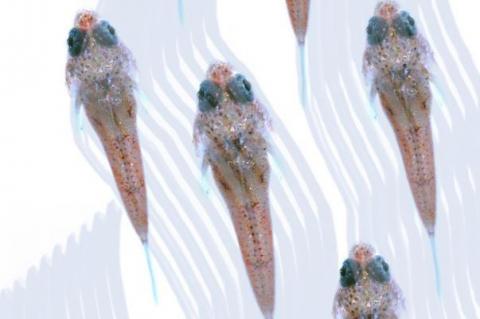

Corrosion can happen fast

The final point I will make about the article is for the benefit of an annual inspection. In my experience, many issues have developed within a cylinder within a year’s period. The photo (left) shows excessive aluminum hydroxide corrosion I found in a cylinder within 365 days of its previous inspection.

Also, back in the 1970s, the University of Rhode Island found that corrosion in a steel cylinder can affect its gas content, and corrosion factors in as little as 100 days. A well-maintained cylinder can go years with no issues. A misused, neglected or abused cylinder can be compromised well within a 30-month inspection cycle.

Frequent

The annual visual inspection process for dive cylinders in the United States is a voluntary procedure developed by divers back in the 1970s; no government agency mandated the process. US divers have been getting their cylinders annually inspected for decades, with no obvious financial concerns.

It is not a perfect system, and some try to get around the practice, but most do not. The more often a cylinder is inspected, the greater chance of catching an issue before it becomes dangerous. It takes a proper visual inspection on all cylinders to help prevent ruptures and other catastrophic events. ■

Download the full article ⬇︎